Planet

We recognise the ever-increasing expectations of our stakeholders, and our primary future challenge is the decarbonisation of our products to support the wider built environment aspirations of delivering zero carbon buildings.

Our business and sector plays a crucial role in the defence against climate change. Today, our products are “climate ready”, offering flood resilience, high levels of thermal performance reducing the amount of energy required to heat and cool homes and assured durability in use spanning generations.

Greenhouse gas emmisions

We manufacture two broad categories of products: those made from clay and those made from concrete. These products are supplied hand in hand to our customers and are used together in building high quality homes and buildings. However, the manufacturing processes are very different and their carbon footprints, whilst similar overall, are built in different ways.

Clay products

Clay is the primary raw material used to make bricks. The clay is typically sourced locally from our own quarries, limiting the environmental impacts of transportation to factories. The clay is ground and then formed into a brick shape using a variety of methods. The grinding and forming process uses electrical energy. At this stage bricks contain significant amounts of moisture which must be removed before they can be fired. This drying process utilises recycled heat from our kilns.

The next stage is the firing of the brick which transforms the relatively weak dried clay into strong durable bricks that will last for generations. During the firing process, the bricks are heated to temperatures of over 1,000 °C, triggering chemical reactions in the clay. Our kilns are fired by burning natural gas and the clay itself also emits carbon dioxide, which we refer to as process emissions during the chemical reaction. Once cooled, the bricks are packaged ready for despatch to our customers. As a result of the emissions created by the burning of gas, as well as the embodied carbon released from the clay during the firing process, the majority of emissions from our clay brick manufacture fall into scope 1.

Concrete products

We make a range of concrete products, from aerated concrete blocks to precast concrete floor beams, using a number of different manufacturing techniques. Traditional concrete is made by mixing aggregates, cement, and water. It is then left to undergo a chemical reaction known as curing which can be accelerated by adding additional heat.

We purchase all of the raw materials, with cement having by far the largest carbon footprint. As such, the majority of the emissions from manufacturing concrete fall into scope 3.

Clay vs. Concrete emissions

It is important to emphasise that both our clay and concrete products contain very similar levels of overall carbon

dioxide emissions per tonne of product. However, the way in which these emissions are reported within the Greenhouse Gas Protocol scopes is very different.

The majority of the emissions associated with the manufacture of clay bricks are direct emissions under our control and are therefore disclosed in scope 1. The majority of the emissions associated with the manufacture of our concrete products are indirect emissions under the control of our suppliers and included in scope 3, and therefore not disclosed in our figures.

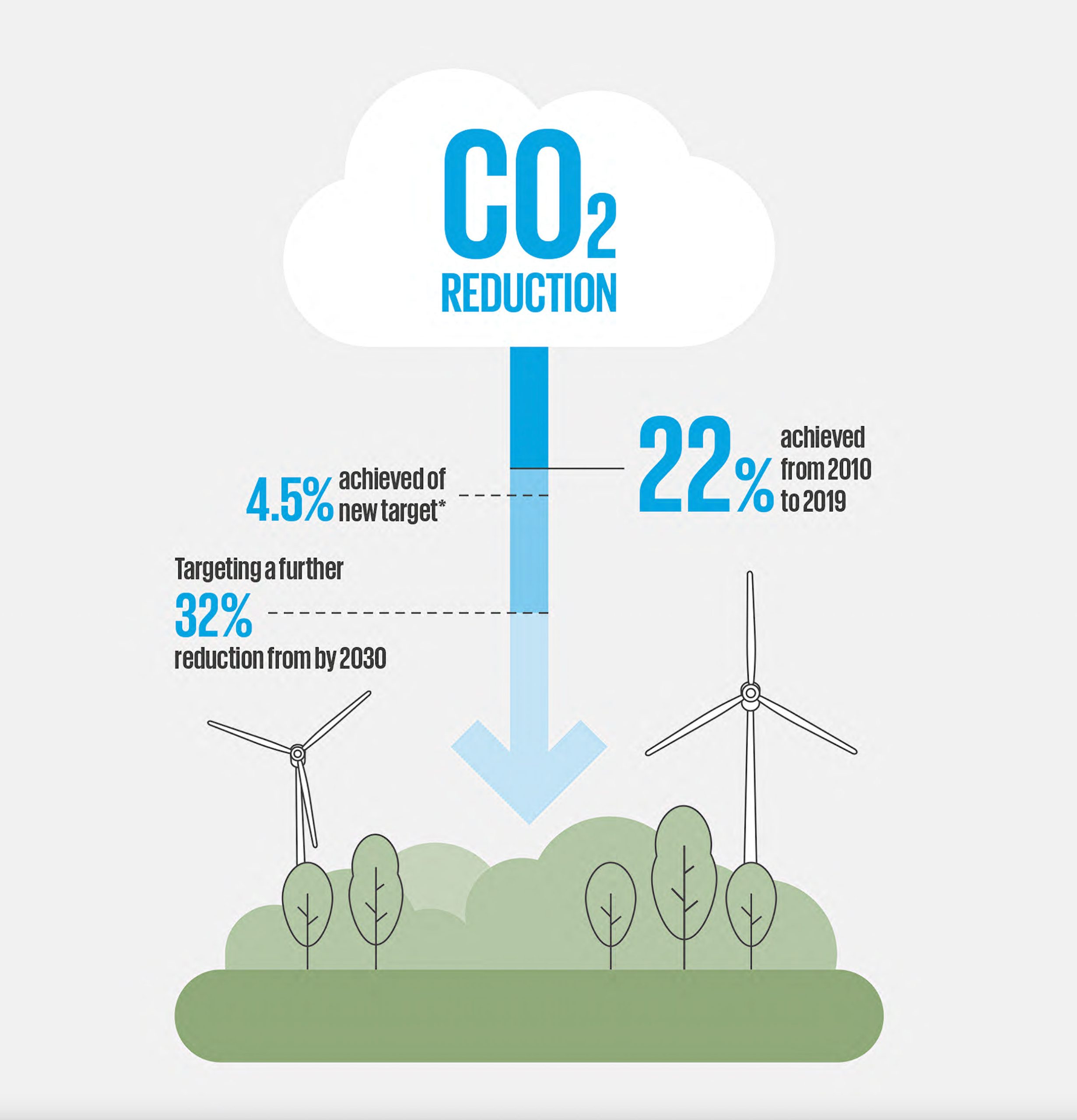

OUR 2030 CARBON REDUCTION TARGETS

To build upon our substantial achievements over the past decade and in support of the UK’s Net Zero Carbon ambition with the Government committing the UK to achieving net zero carbon emissions in 2050, we have set ourselves the following challenging reduction targets for 2030, covering our direct (scope 1 and 2) emissions:

- Group CO2e intensity (CO2e / tonne) – 32% reduction versus 2019 baseline (assuming 2019 product mix)

- Clay products intensity (CO2e / tonne) – 33% reduction versus 2019 baseline

- Concrete products intensity (CO2e / tonne) – 80% reduction versus 2019 baseline

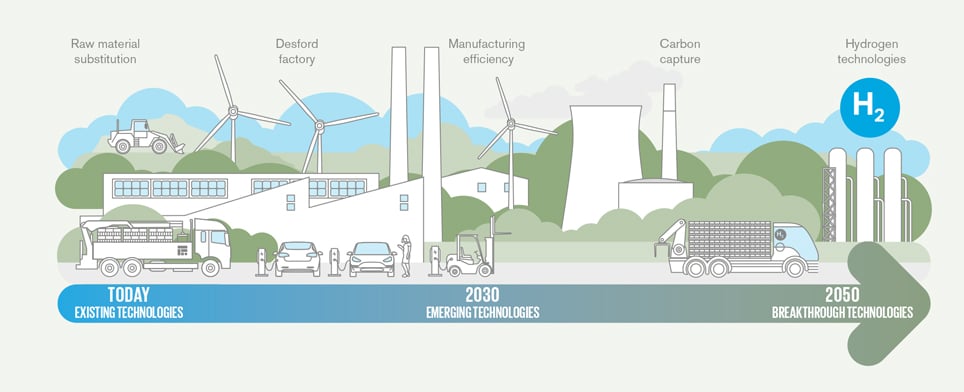

Our targets are ambitious. We will deploy both existing and new technologies over the next decade to achieve our goals, as well as closely controlling how we manage our existing operations.

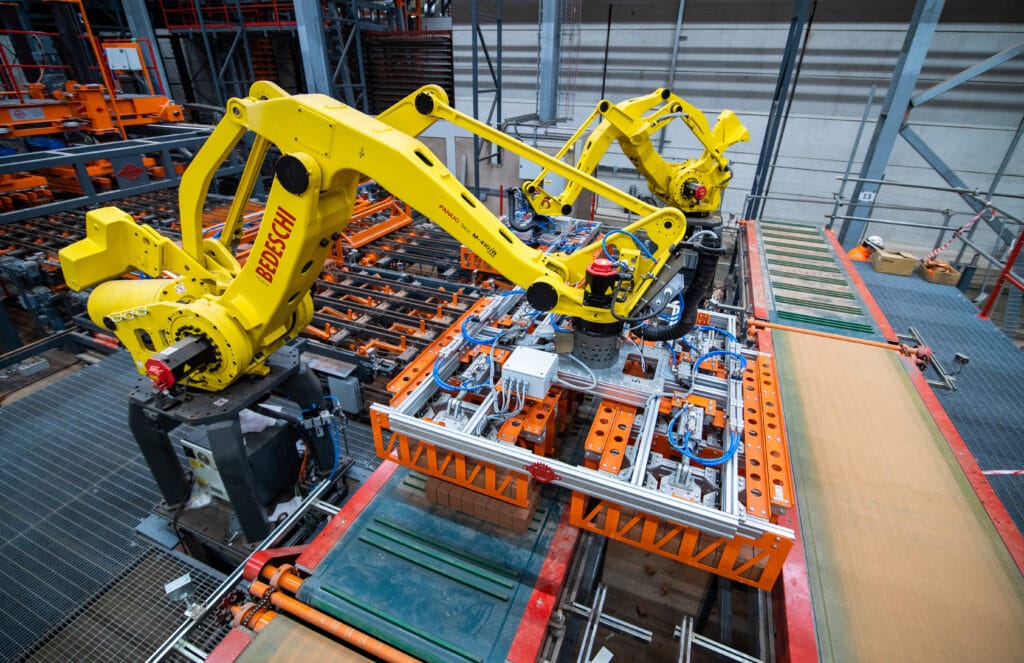

Aside from the new Desford brick factory investment we expect to require only modest levels of capital investment contained within our existing guidance of £12m of annual maintenance capital expenditure though this will be kept under review. We will deliver our 2030 target in a number of ways. We have already switched to procuring 100% of our electricity requirement from renewable sources removing all of our scope 2 emissions in 2020.

In addition to this, we will continue to investigate the possibility of investing in our own renewable electricity generation capacity which whilst not reducing our emissions relative to purchasing green electricity from the grid, would allow us to contribute to increasing the UK’s capacity, to generate renewable electricity as well as potentially reducing our cost of electricity.

FOCUS ON RENEWABLE ENERGY

In 2020 we switched to purchasing 100% renewable electricity. Whilst this positive step reduces our scope 2 emissions to zero we always wanted to do more. For the UK to reach its net zero ambitions the electricity grid, which still relies upon significant gas and coal fired generation, needs to be decarbonised. Working with an external partner, a global leader in the management and development of solar energy projects, we have committed to purchasing around 70% of our electricity requirement from a dedicated solar farm, exceeding 200 acres in size to be situated in Nottinghamshire. This commitment approximating to £50m over 15 years from 2025 will facilitate the delivery of 60 GWh of additional solar generation capacity to the UK, enough to power 17,000 average homes. This arrangement will provide us with secure renewable energy with price certainty for a 15-year period commencing in 2025. Alongside this, we are investing in on-site renewable electricity generation at a number of our factories in order to generate 10% of our electricity requirement from 2025.

Again, this adds incremental renewable energy generation capacity whilst also providing a low-cost electricity supply avoiding the sizeable transmission charges associated with having power delivered through the grid. We were hoping to have delivered the first of these projects in 2021 although global supply chain pressures ultimately meant this wasn’t possible.