Paving the highway to hydrogen

As part of our extensive future-proofing strategy, we are delighted to have completed the first phase of hydrogen trials at our Measham brickworks factory in North-West Leicestershire.

Whilst proposals for inclusion of hydrogen into the national grid are still in their infancy, we have adopted a proactive approach, extensively trialing 20% hydrogen blends across its brick ranges.

This forward-thinking strategy will allow us to assess the possible effects of hydrogen on its products, processes and equipment, well in advance of any changes to government policy.

David Fox, Capital Engineering Manager at Forterra, explains the objectives of these trials, stating, “Our main priority is to determine whether the use of hydrogen blends would have any aesthetic or performance-related impact on the finished product, and whether the blend can be used with existing kiln equipment.

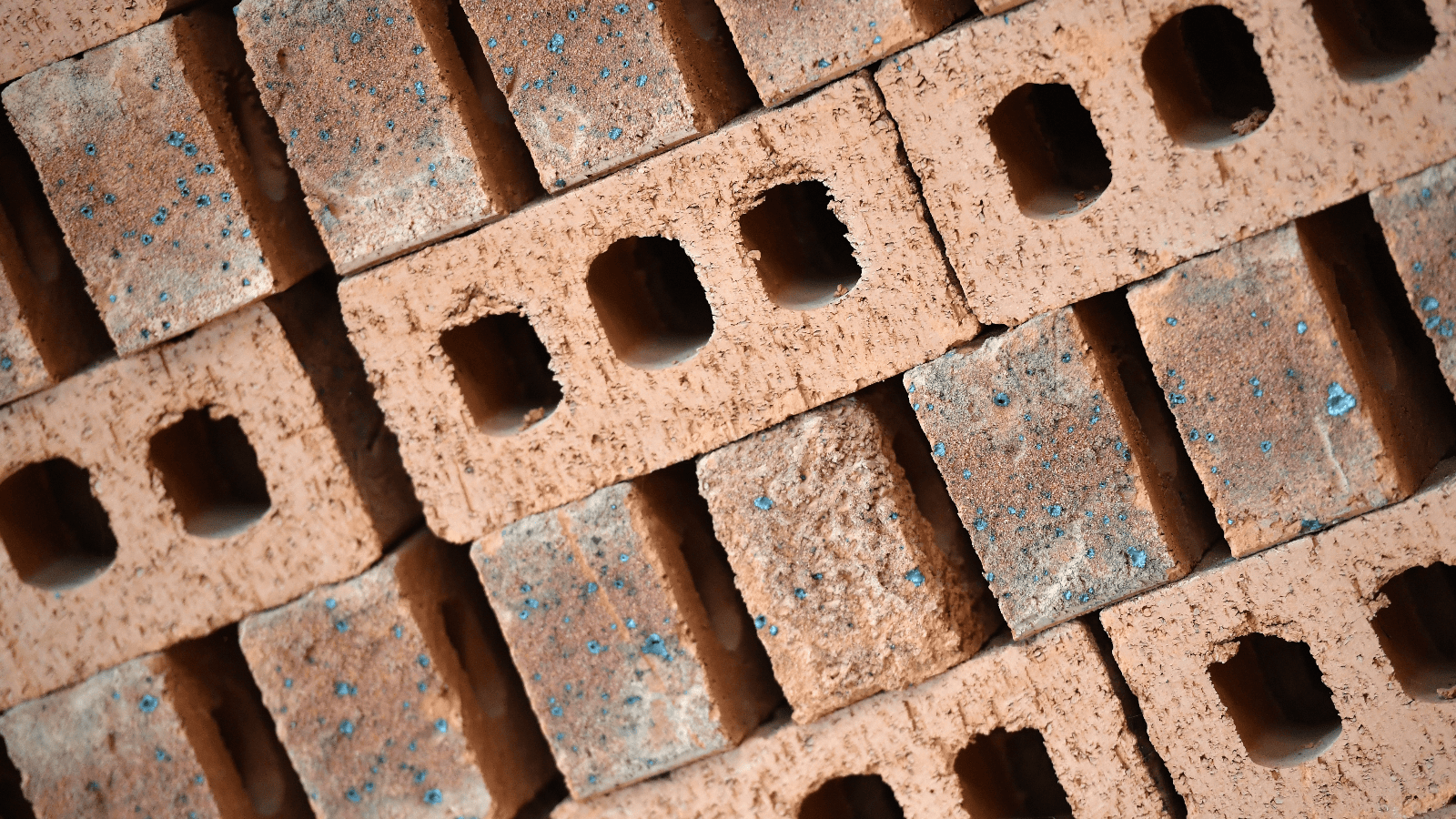

“Our bricks are renowned for their unique range of textures and colours and for their high performance and durability. We’re therefore glad to have had our predictions confirmed: the 20% hydrogen blend shows no impact on these criteria. Moreover, it is fully compatible with existing kiln equipment.

“The latter is especially encouraging. Our kiln equipment tends to have a lifespan between 25 and 40 years: replacing it would incur significant carbon costs.”

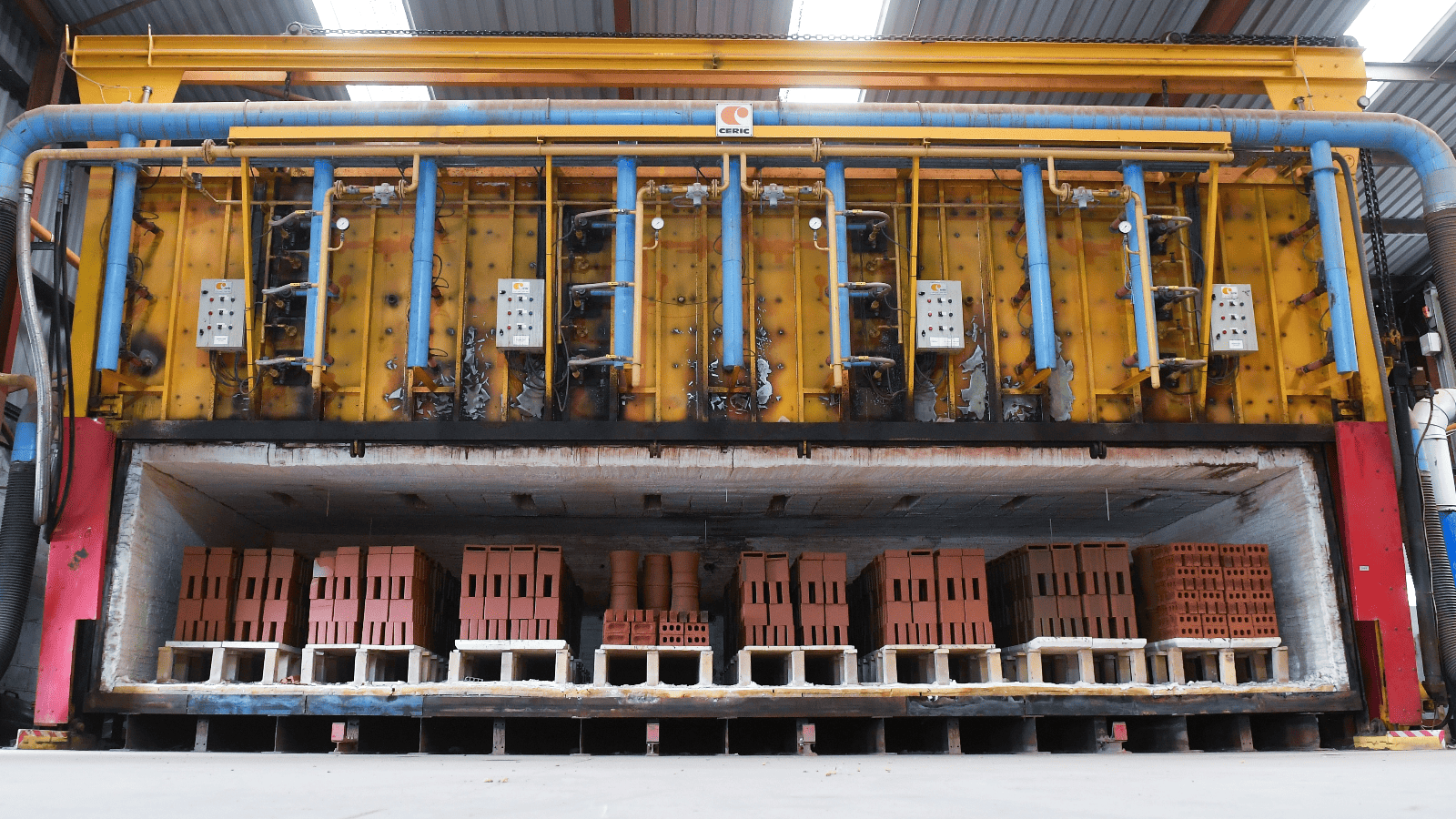

Instead of constructing trial-specific kilns, we used existing machinery to see if its current legacy kiln equipment could adapt to the new hydrogen blend.

In addition, we partnered with Air Products, a leading chemical industry company, which provided a hydrogen storage facility and a pressure and flow regulation system. This collaboration allowed us to blend different percentages of hydrogen with natural gas for the purposes of the trial.

To ensure consistency in the testing process, we tested its Measham buff bricks and Desford red bricks, with special attention given to maintaining the distinctive red hue of the bricks. As a reducing agent, hydrogen can reduce the amount of oxidation that takes place within the kiln, and therefore potentially affect the final colouration of the brick product. To offset this, oxygen levels had to be carefully monitored and adapted during the trials, to ensure the renowned rich red hue of the final brick was maintained.

The initial results from these trials have suggested that there are no major impacts to brick quality, aesthetic appeal, or to the kiln when using the 20% hydrogen blend. The next step is to observe the effects of this blend of hydrogen on different types of clay, thereby determining whether the blend could be implemented with equal capacity across our range of brickworks.

The initial results show that our current production facilities are more than capable of maintaining our renowned brick quality with this new hydrogen blend, which is exactly as we’d predicted.

As decarbonisation becomes a critical objective for industries worldwide, the 7% reduction in carbon output achieved through the use of hydrogen fuel in these trials is also a welcome bonus.

These hydrogen trials align with the our broader commitment to achieving ambitious environmental, social, and governance (ESG) targets.

This commitment is reflected in our other developments and investments made over the past year, including a solar farm, a new fuel-efficient of trucks, and new reduced-plastic packaging solutions. We also opened our brand new Desford factory in May 2023, the biggest, most efficient brick factory in Europe.