Stairs & landings

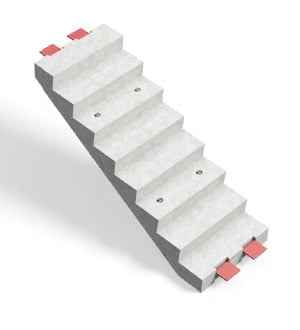

Bison Precast’s adjustable steel moulds for stairs, landings and balcony units can meet the requirements of even the most demanding projects. Close working with project architects and designers ensures the structural and commerical viability of its products, whether standard or bespoke. Each precast concrete unit is designed and manufactured to meet the specific requirements of each project, with our in-house design team on hand to provide immediate guidance and information. The use of precast staircases offers immediate and safe access to upper levels during the build process.Our staircases are manufactured in precision steel moulds offering flexibility of rise and going adjustment. We also offer high quality bespoke moulds for non-standard staircases.Standard or bespoke staircases & landings

Standard staircase

Bespoke staircase

Stairs and landings

Stairs and landings are available in a variety of standard arrangements. Alternatively they can be tailor-made to suit the application.

HIGH PERFORMANCE

- Inherent fire resistance and excellent sound reduction qualities

- Factory manufactured for improved consistency, accuracy and quality

COST OF CONSTRUCTION

- No propping or expensive formwork

- Immediate safe access for follow-on trades

- Increased speed of build

- Suitable for all construction types, in all sectors

QUALITY

- All precast concrete products and processes comply with relevant standards and are manufactured in accordance with BS EN ISO 9001

- Stair components are CE marked against BS EN 14843

- Accredited to BS EN 14001 and BES 6001 responsible sourcing

SERVICE

- Available nationwide either supply only or supply and install

- Design support provided from concept through to project completion