Hollowcore & solid floors

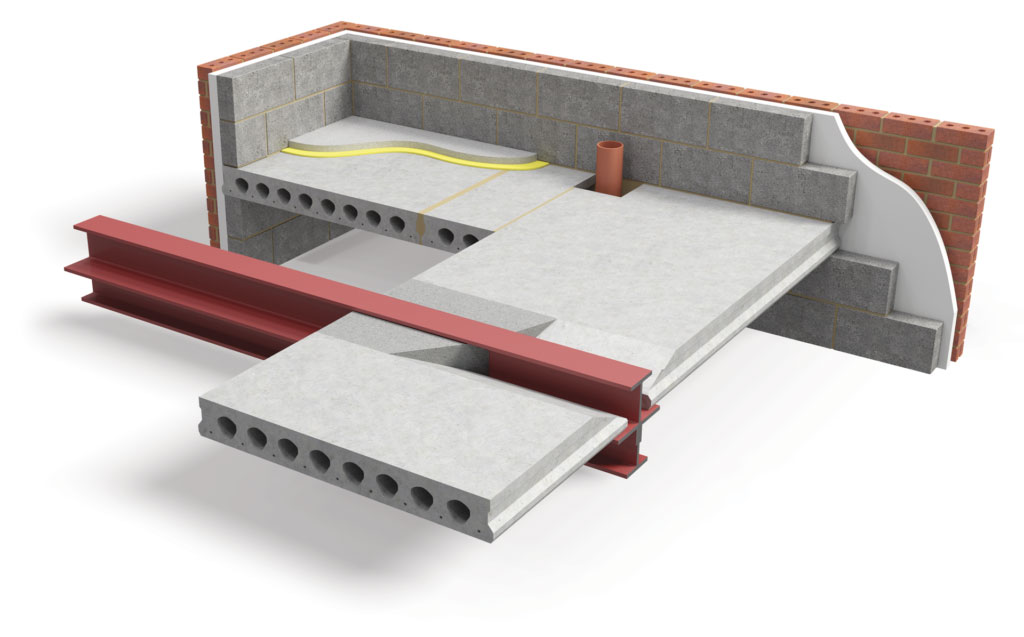

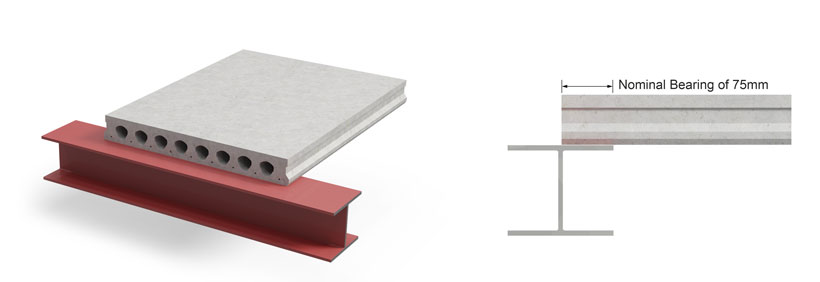

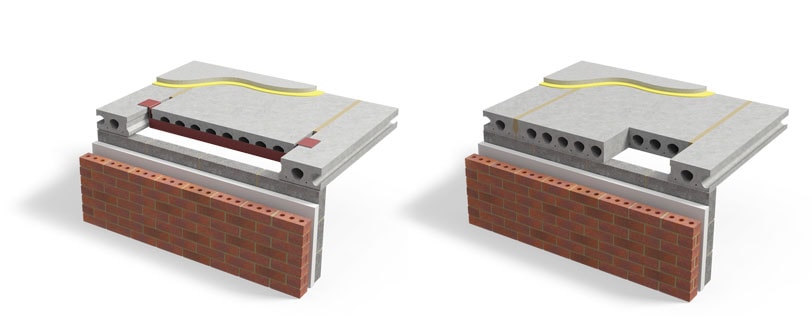

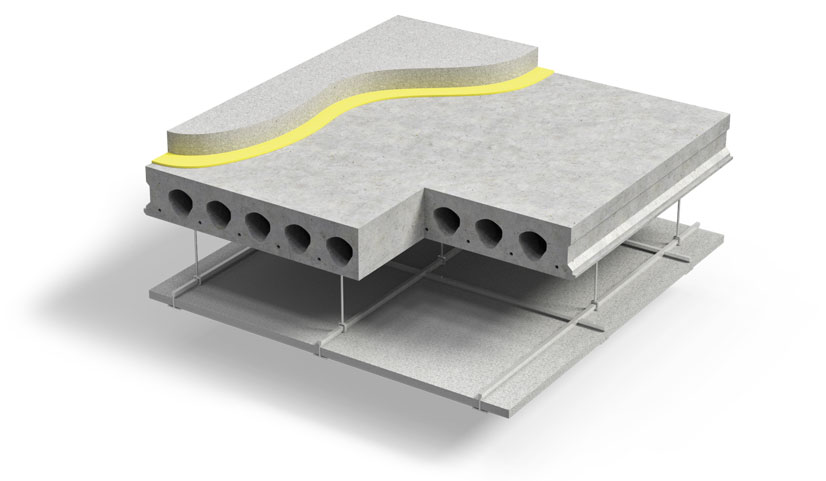

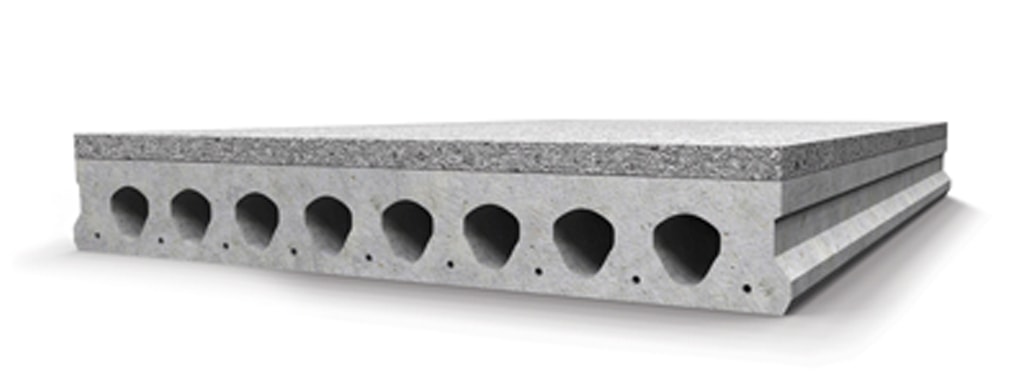

Excellent sound-reducing qualities, durability and inherent fire resistance make our hollowcore slabs the solution of choice for apartments, care homes, hospitals and commercial projects. Our precast hollowcore floors are available in sections 150, 200 and 250mm deep. They can be delivered nationwide on a supply and install basis by specialised teams from Bison Precast, or supply only for installation by the main contractor. Our precast hollowcore floor unit offers the ideal structural section, reducing deadweight whilst also providing maximum structural efficiency within the hollowcore slab depth. Precast floors are available with a variety of factory-formed notches, slots and reinforcement arrangements to offer a range of structural design solutions.Hollowcore & solid flooring products

Hollowcore floors

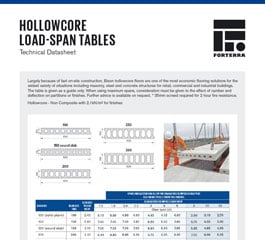

HOLLOWCORE FLOORS

Hollowcore floor slabs have excellent sound-reducing qualities, durability and inherent fire resistance making them the ideal solution for apartments, care homes, hospitals, schools, universities, hotels, custodial facilities, industrial and commercial projects.

Solid Floors

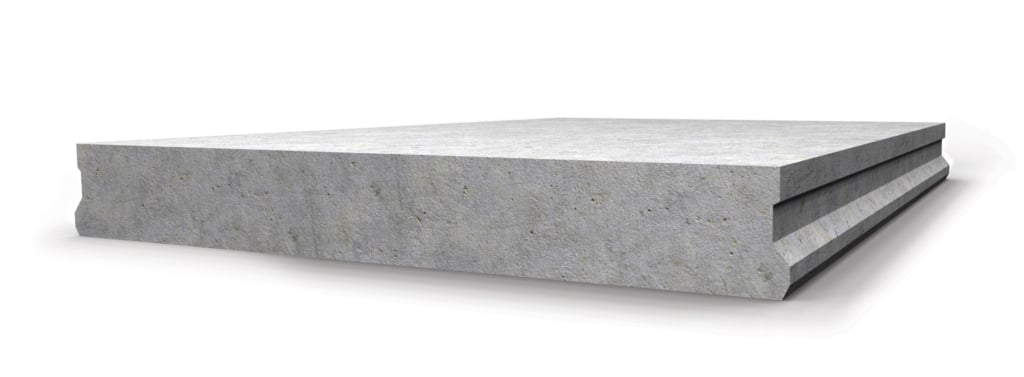

SOLID FLOORS

Our solid floor prestressed units provide effective solutions for projects in a variety of sectors. They are manufactured in 100mm, 150mm and 200mm depths and are suitable for use in high-rise apartments, stadia, industrial and commercial projects.

DESIGN BENEFITS

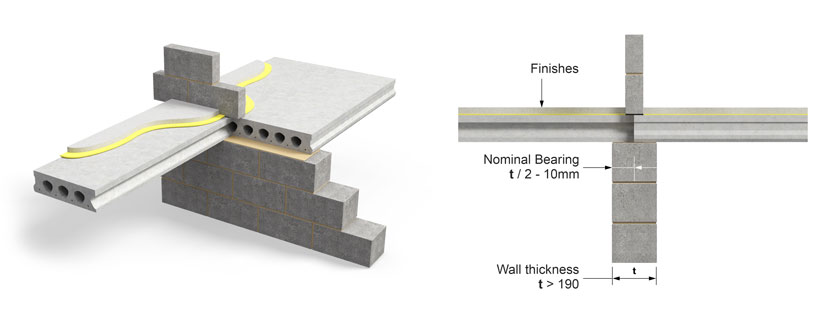

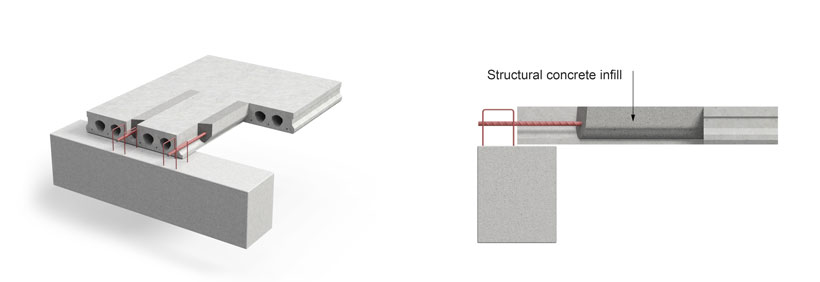

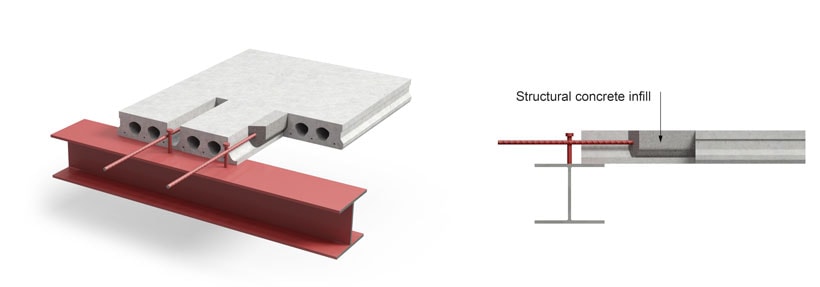

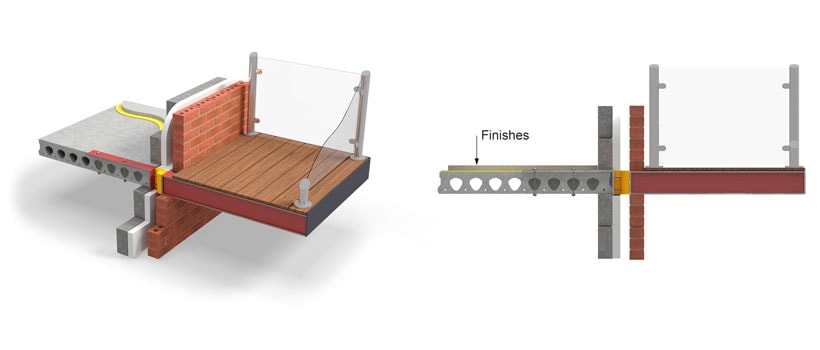

- Can be used in all types of structure – masonry, steel and concrete

- Ideal structural section by reducing deadweight

- Excellent sound reducing qualities and inherent fire resistance

- Compatible with Robust Details for Part E of Building Regulations

- Design support provided from concept through to project completion

- Flexibility in design approach

- Enhanced spans

- Excellent sound and fire resistance

- Pre-bonded insulation (insulated hollowcore)

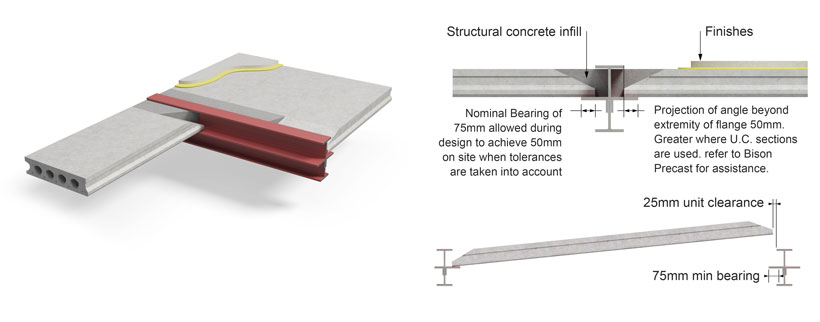

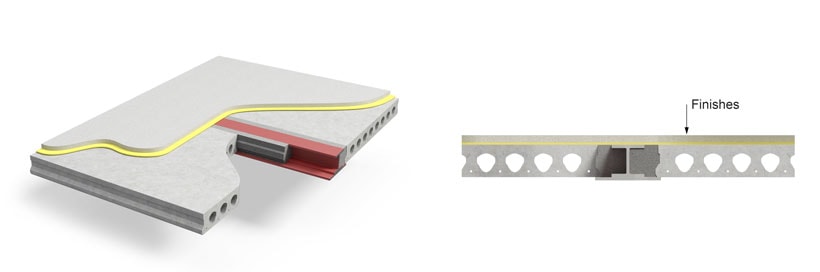

- Floor slabs and steel beams act compositely together to enhance load capacity of steel beams (composite steel beams).

- Provides a structural and cost-efficient solution for steel frames (composite steel beams)

CONSTRUCTION BENEFITS

- Clear, unpropped spans provide an immediate working platform

- Fast and simple to erect

- Cast in lifting hooks

- Easier installation of services, with holes and notches pre-formed during manufacture

- Virtually maintenance free – concrete is not subject to damage from rot or insect attack

- Concrete floor eliminates squeaky floors

- Precast floors are manufactured on high quality steel beds and, where appropriate, are suitable for direct decoration. Exposed soffits accommodated upon request.

- Nationwide coverage

- Supply only or supply and install services available

- One or two-hour fire resistance

- Type ‘A’ finished soffit

- Shelf angle bearing

- Sound resistance – noise transfer performance

- Reduction of in-situ concrete

- Design support provided from concept through to project completion

- Can be used in all types of structure – masonry, steel and concrete Reduces total tonnage of steel beams by up to 40% (composite steel beams)

- Reduces the number of components to be erected (composite steel beams)

- Reduced site operations (composite steel beams)

- Optimisation of shear studs (composite steel beams)

SUITABLE APPLICATIONS

- Residential – standard housing, retirement apartments, high-rise apartments, residential (single and multi-occupancy), care homes

- Education – schools, universities

- Industrial and commercial – office buildings, retail, distribution, manufacturing

- Student accommodation

- Stadia

- Leisure – hotels, leisure centres

- Custodial – prisons, custody suites

- Healthcare – hospitals, healthcare centres

- Car parks – steel frame, precast frame

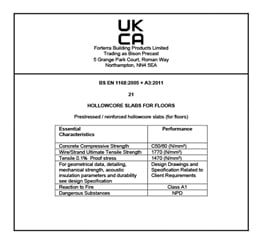

QUALITY BENEFITS

- Manufactured under factory-controlled conditions to maintain quality consistency

- All precast concrete products and processes comply with all relevant standards and are manufactured in accordance with BS EN ISO 9001

- Accredited to BS EN 14001 and BES 6001 responsible sourcing

- Precast components are CE marked against BS EN 1168

- Preformed site services